How to turn manufacturing data into knowledge

A true Manufacturing Intelligence (MI) system shouldn’t be confused with a Business Intelligence (BI) application, which is designed for corporate use rather than specific factory floor operational needs.

The primary functions of MI are to:

- Collect – bring data together from many sources.

- Order – structure gathered data for ease of use.

- Analyse – analyse data across production sites for reporting purposes.

- Visualise – create visual data summaries for decision making.

- Disseminate – automate data transfer from the plant to the board room and vice versa.

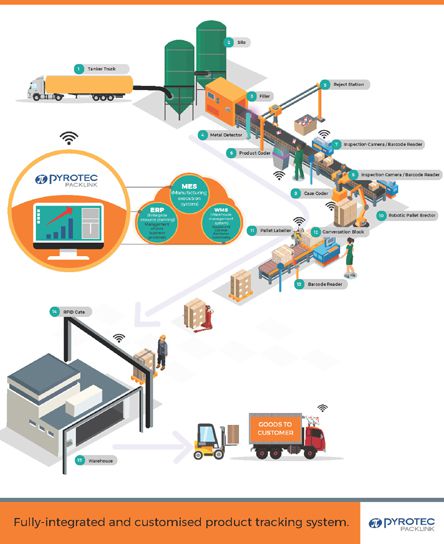

To achieve this, PackLink from Pyrotec is customised software that provides a fully integrated coding and labelling tracking system. Pyrotec PackLink assists customers to increase line visibility while improving efficiency by tracking waste, labour and resources; and limiting downtime by enabling critical decisions to be made on the fly. In short, Pyrotec PackLink helps customers to achieve overall equipment efficiency.

Manufacturers achieve overall equipment efficiency by constantly monitoring their lines and immediately implementing corrections when required. "Our fully customised software does this for our customers," explains Shaun Pillay, Pyrotec PackMark’s National Sales Manager. Designed specifically for individual manufacturer’s needs, Pyrotec PackLink offers touchscreens (HMI) for easy job selection and monitoring. It also features integrated barcode scanners and/or cameras to limit human intervention and increase efficiency.

"For customers interested in this software, a feasibility study is undertaken to determine requirements. Customers’ existing equipment can be integrated through the software, and recommendations for more efficient, cost-effective equipment from Markem-Imaje may be advised," Shaun adds.

As an example of what’s possible, Pyrotec PackLink software integrates into an ERP/MES system that networks printers, print and apply and desktop printers, camera systems, barcode readers, scanners, and touchscreens to provide full line visibility for production and line managers.

Because the Pyrotec PackLink software is customised and developed inhouse by Pyrotec, customers can build onto the system as and when budgets allow, or business requirements dictate. "We can begin with a simple integration/tracking system and expand on this as required," Pillay points out.

To integrate your hardware and turn manufacturing data into knowledge, contact Pyrotec PackMark today.

- Why choose premium labels for the nutraceutical industry? A look at Pyrotec PackMedia's expertise 15 Feb 2024

- The perfect coding and labelling solutions for personal care and cosmetic products 3 Nov 2023

- Revolutionising retail: Klip Strip and other display merchandising solutions from Pyrotec PackMedia 13 Oct 2023

- The end-of-line solution you've been waiting for 29 Mar 2023

- Uncluttered labelling for household cleaning products 28 Mar 2023

PyrotecPyrotec is a proudly South African company with its focus aimed firmly on the future. Its five brands - Pyrotec PackMark, Pyrotec PackMedia, Pyrotec PackLink, Pyrotec PackWorx and Pyrotec Finance - make this an industry-leading company that specialises in a comprehensive range of coding and labelling equipment, on-pack informational and promotional devices, merchandising solutions, development and manufacturing of automated systems for the packaging and manufacturing industry and making finance options available to customers. Pyrotec's software offering ensures product integrity, optimises coding activities, and helps secure centralised data management systems and label tracking systems. |